ISPM 15 - Backgrounds and Challenges

<p>Within the scope of the International Plant Protection Convention (IPPC) headed by the Food and Agriculture Organization of the United Nations (FAO), a “Regulation of Wood Packaging Material in International Trade” was adopted, which describes globally recognized measures for plant health treatment (FAO 2003). This regulation is the International Standards for Phytosanitary Measures No. 15.</p>

ISPM 15 - Why is it actually necessary?

Within the scope of the International Plant Protection Convention (IPPC) headed by the

Food and Agriculture Organization of the United Nations (FAO), a “Regulation of Wood Packaging Material in International Trade” was adopted, which describes globally recognized measures for plant health treatment (FAO 2003). This regulation is the International Standards for Phytosanitary Measures No. 15.

The Directive aims to minimise the risk of the introduction and/or spread of quarantine pests associated with wood packaging material and dunnage in international trade. In principle, raw wood which has not been treated using phytosanitary measures represents a transmission path for harmful quarantine pests and is therefore capable of causing considerable economic damage to importing economies.

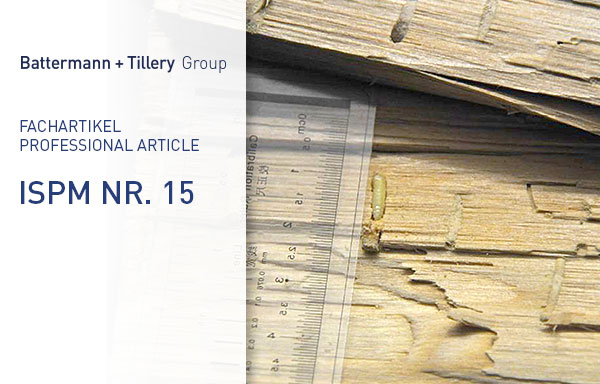

In the area of wood-damaging insects, a basic distinction must be made between fresh wood pests and dry wood pests. Fresh wood insects infest living tree populations in the wild, and dry wood insects infest dried wood and wood which has been processed and used in construction. ISPM 15 specifically focusses on the aspect of fresh wood insects and serves to prevent the introduction of plant pests into importing countries in order to avert the destruction of their stocks of living plants (trees, etc.).

The damage to national economies results from the fact that fresh wood pests introduced into the importing countries infest tree populations not only belonging to private individuals, but also to municipalities and cities. Depending on the type and extent of the infestation, damage can often be limited only by large-scale clearance of forests and woodland. Costs are thus incurred for the treatment and/or clearing of the infested plants as well as for the subsequent reforestation. When extrapolated over the surface area of an entire country, this can inevitably lead to damage running into billions. If the spread of the fresh wood pest cannot be contained, the costs incurred are not simply one-off, but are recurring. Two examples of the above are the introduction of the Asian longhorn beetle or the brown marmorated stink bug in Europe.

The measures set out in ISPM 15 therefore aim at killing fresh wood insects and, in particular their larvae, present in the wood before it is processed into packaging timber or dunnage. Packaging timber is packaging material made of raw wood with a minimum thickness of 6 mm. The above however does not include processed wood, which has already undergone heat treatment during production, such as plywood, chipboard, OSB boards or MDF boards.

Regardless of the type of treatment used, wood packaging material must be made of debarked wood. However, any number of visually identifiable and distinctly separate small pieces of bark may remain on the timber if they are:

- less than 3 cm in width (regardless of the length), or

- more than 3 cm in width if the total surface area of each piece of bark is less than 50 cm².

Prior to treatment with methyl bromide and sulfuryl fluoride, the bark must be removed because the presence of bark on the wood may affect the effectiveness of the treatment. In the case of heat treatment, the bark can be removed before or after treatment.

Since the last updating of ISPM 15 in 2018, the following methods have been presented as being appropriate measures for the eradication of insect pests:

- Heat treatment using a conventional heat or drying chamber (HT): The timber packaging material must be heated according to a particular time-temperature plan and reach a minimum temperature of at least +56°C in the core of the wood for a duration of at least 30 minutes.

- Heat treatment using dielectric heating (DH): When the dielectric heating method of heat treatment (e.g. using microwaves or radio waves) is used, the wood packaging material must be heated in such a way that a minimum temperature of +60°C is reached for one full minute throughout the entire cross-section of the wood, including its surface.

- Methyl bromide fumigation (MB): Timber packaging material can be fumigated with methyl bromide. The method of treatment specifies minimum temperatures, treatment times and minimum gas concentrations.

- Sulfuryl fluoride fumigation (SF): Timber packaging material can be fumigated with sulfuryl fluoride. The method of treatment specifies minimum temperatures, treatment times and minimum gas concentrations. Timber packaging material consisting of a piece of wood with a cross-section exceeding 20 cm as its smallest member may not be treated with sulfuryl fluoride. Timber packaging material with a moisture content of more than 75% (on a dry mass basis) may also not be treated with sulfuryl fluoride.

In this context, it should be noted that treatment of wood with methyl bromide is not allowed in all countries. For example, the use of methyl bromide is prohibited in the European Union.

All packaging timber which has been treated in accordance with ISPM 15 has to be correspondingly marked by the companies performing the treatment, and who are registered with and regularly inspected on a random basis by the relevant authorities in line with a specific standard. The marking indicates the method of treatment used (HT, DH, MB or SF), the abbreviation of the competent authority including the country code, as well as the registration number of the company carrying out the treatment.

ISPM 15 has now been officially ratified by over 100 countries worldwide including, for example, the USA, Russia, the European Union, China and Japan. In this context, it should be noted that in certain countries, other national regulations apply in addition to the regulations stated in ISPM 15.

Consequences of non-compliance using the example of the USA

Reasons for the rejection of the import of consignments with timber packaging material on grounds of phytosanitary issues are basically the lack of any form or the incorrect form of labelling as stipulated by ISPM 15, or the presence of live fresh wood insects or their larvae despite the existence of ISPM 15 labelling.

ISPM 15 basically states that in the event of non-conformity at the point of entry, a procedure can be applied which provides for renewed treatment, disposal of the packaging material or rejection of the consignment. The type of procedure used is decided by the importing country.

In the case of the USA, the shipment is usually barred from entering the country by the competent authority, the USDA (United States Department of Agriculture).

There is currently a clear trend that inspections on import shipments by the said authority in the USA have increased considerably in recent times and that, as a result, the rejections of shipments have increased as well. This is particularly true for the finding of live fresh wood insects. The barring or rejection of the import does not apply solely to the rejected packing unit found to have the live infestation, but to the entire consignment. In the context of a project shipment, a large number of packing units may be affected by the rejection. As a result of the barring of the import of the consignment, the consignment must now either be handled in a country that allows temporary importation for the treatment or disposal of packaging timber, or the consignment must be returned to the country of origin for further treatment there. In the case of the USA, the respective EANs (Emergency Action Notifications) specify corresponding exclusions for temporary export for treatment to Canada and Mexico and rules out treatment in the USA.

As a result of these circumstances, the parties involved in the cargo shipment sometimes incur considerable supplementary costs due to the additional freight and treatment operations required, and which may well amount to a total of several hundred thousand Euros for larger project consignments.

In addition to the said additional costs, the USA has also imposed heavier penalties for non-compliance with ISPM 15 since 01 November 2017. In the event of infestation of the packaging timber having ISPM 15 marking and which thus has been declared as being treated, the circumstances are now interpreted by the USDA as being a case of fraudulence. For example, fines having the same value as that of the rejected consignment can be imposed even on the first violation of the regulations. This aspect also represents a considerable cost factor primarily for high-value project shipments.

As such, even a single violation of ISPM 15 can result in costs in the millions.

A problem here is that the objection at the point of entry and the resulting further procedural action depends to a considerable extent on the decision made by the responsible official, and this decision is not always comprehensible to all parties involved, or clearly documented. For example, objections may also be raised with packaging timber exhibiting feeding passages, although this does not actually constitute a reason for objection within the scope of ISPM 15. Likewise, the decisions made on the basis of ISPM 15 depend on the type of pest infestation. For example, there could also be objections about consignments that are infested with dry wood insects, even though this type of pest infestation is not actually covered by ISPM 15. In addition, the only documents issued are ‘Emergency Action Notifications’, without any further information (e.g. photo material/sample material) being submitted by the authorities, and an independent inspection of the consignment in the port of import is usually not permitted. The parties involved in the transport operation are therefore ultimately at the mercy of the decisions of the USDA without any possibility of redress.

Consequences for the insurance industry

The infestation of packaging timber with fresh wood insects is not considered as being transport-related damage which is covered by a standard cargo insurance policy. In light of the behaviour of fresh wood insects, infestation of packaging timber with fresh wood insects will have occurred only prior to the transport operations or the production of the packaging (fresh wood insects are, by definition, only the infestation of living trees). As such, the impairments are already present prior to the start of transport operations and thus are classified as qualitative impairments or inherent vice. This is a particular problem which is underestimated by shippers, and represents a significant cost factor which is not covered by any insurance policy.

The presence of fresh wood insects in the packaging timber despite it having been treated according to ISPM 15 or having been labelled as having been treated always indicates that no treatment has been carried out, or that it has not been carried out correctly. Thus, in the event of an objection as a result of non-compliance with ISPM 15, the shipper will generally hold the packing company liable and, if the treatment was not carried out by the same, the company which carried out the treating of the timber as per ISPM 15. In most cases, this then results in the involvement of the business liability insurance of the packing company or the treating company.

Recommendations for packing companies/timber-treating companies

In the event of a claim, a special problem which has to be considered is that, in principle, it must be proven that the treatment was carried out in an appropriate manner. However, it is not possible to prove that timber has been subjected to heat treatment by inspecting the condition of the packaging timber since the performing of heat treatment in accordance with ISPM 15 does not cause any detectable changes in the treated wood, or in the structure of the wood.

Of greater relevance and importance is the choice of the suppliers of the fresh wood (supplier audits), and the quality of the purchased fresh wood itself. Suppliers could, for example, be required to provide fresh wood pre-sorted on the basis of the degree of insect infestation. This is of particular relevance, in light of the fact that there is currently a large quantity of insect-infested fresh wood on the market due to the very hot and dry summer 2018.

The fresh wood should also be subjected to a detailed incoming goods inspection upon its delivery in order to identify any potentially problematic wood before any treatment, and to be able to undertake mitigating measures.

The treatment performed should be substantiated with high-quality documentation detailing the full process chain with treatment reports, and by ensuring the full traceability of the timber. Cold spots, which may exist in the heat-treatment chambers, and/or inaccurate or defective probes for monitoring the temperatures attained in the core of the wood can result in the failure to successfully kill any insect infestation which may exist within the wood. Regular maintenance, care and inspection of the heat-treatment chambers and the measurement system involved are therefore of vital importance. The above should go beyond the mandatory legal requirements.

The success of the treatment processes should likewise be regularly checked by the companies on a random basis before the treated wood is used as packaging timber. It could also be worth considering subjecting all fresh wood to KD treatment (kiln drying), which is normally used to dry wood and reduce its moisture content. The temperatures reached in the treatment chamber and the duration of treatment exceed the requirements of the heat treatment process as stipulated in ISPM 15 and would offer an additional safety factor. By appropriately communicating the reasons behind the changes to the customers (packing companies), the ensuing higher costs of packaging timber would most likely be accepted by the market.

Recommendations for shippers

A change of packaging material or dunnage material used by shippers from wood to other materials such as metal, is generally not an acceptable alternative.

The use of metal would result in a significant increase in the costs of the packaging material. Furthermore, freight and handling costs would also rise due to the increase in the weights of the consignments and/or the packing units themselves.

Furthermore, the use of metal instead of wood has considerable disadvantages regarding the issue of cargo-securing, and leads to an increase in the risk of damage to the consignment in the course of transport, as the frictional forces generated by metallic materials are lower than those generated by timber-based materials. In addition, through its flexibility, timber can absorb the mechanical stresses exerted during transport up to a certain extent. If steel were to be used, for example, these forces would be transmitted directly into the packaged goods themselves.

In order to avoid the occurrence of any claims regarding the timber packaging and the corresponding economic consequences, shippers should undertake a more detailed inspection of the packaging material provided, or the timber provided for the making of their own packaging (if applicable). In addition, the suppliers of the packaging or packaging timber should be subjected to regular audits, and should be required to submit high-quality treatment reports detailing the complete process chain in order to minimise the risk of the later claims regarding the timber packaging in the importing country. The decision of which suppliers are to be used should be made by considering only those who provide high-quality packaging material. Although the above may result in higher procurement costs, it must not be forgotten that the use of low-cost and low-quality packaging timber may be accompanied by considerable consequential costs as described above. Likewise, it may also be worth considering changing the supply contracts with the packaging suppliers regarding the issue of liability in the event of any possible objections due to a violation of ISPM 15.

Due to the problem that, in the event of a claim, the entire consignment stated on the corresponding Bill of Lading is generally rejected, when planning the transport operations, consideration should also be given to dividing the consignment over several Bills of Lading and/or to ship the consignment under separate Bills of Lading, if possible.

All in all, it is recommended that shippers develop effective strategies to find ways to comply with the current legislation. In this respect, choosing the right partner is most definitely of paramount importance.